المنتجات الساخنة

Predictive maintenance in mining industry: grinding mill case

2022year1month1day This work aims to present a state of the art of recent works in predictive maintenance using machine learning algorithms including deep learning algorithms to end up with a synthesis of all cases that use predictive maintenance, and propose a Data

Contact

Ball Mill Maintenance Process and Methods Mining Pedia

The maintenance of the ball mill is of great significance in ensuring the normal operation of the equipment, extending the equipment lifespan, and improving production efficiency.

Contact

Maintenance reliability planning AssetCare for grinding

2023year11month15day Applications include ball mills, rod mills, autonomous grinding (AG) mills and semi-autonomous grinding (SAG) mills. Implementing an asset management plan on

Contact

Mill maintenance – 3 simple ways to keep your

2017year12month19day With the grinding mill critical to a plant’s throughput, it pays to ensure mills receive the necessary care and maintenance. Too often mill maintenance is reactive, occurring due to a breakdown. The result is

Contact

Milling Operations: Reviewing maintenance

2022year5month30day A simple flour mill with a capacity of 300 tonnes of wheat per day (approximately 5,000 cwts or 225 tonnes of flour per day) may have at least as many maintenance items and a variety of input/output devices

Contact

卧式磨机 SKF SKF

2024year4month3day Predict, plan and optimize horizontal grinding mill maintenance to reach highest performance. SKF’s new pay-for-performance business model makes this

Contact

Grinding mill services - Metso

Grinding mill maintenance and repairs. Proper maintenance and repairs not only help extend mill life, but also allow you to optimize your parts supply, manpower scheduling, and

Contact

Grinding Mill Services - Services - HMR

Onsite machining. Mill inspection and monitoring. Troubleshooting and diagnosis of mill operation and reliability issues. Redesign/ rebuild for improved performance and efficiency extending equipment service life.

Contact

Maximizing Ball Mill Performance: A

2023year6month15day Here are some of the reasons why ball mill maintenance is important: 1. Prevents Breakdowns. Regular maintenance tasks, such as lubrication, alignment, and inspection, can help identify potential

Contact

Ball Mill Cleaning Maintenance Guide:

2024year4month5day Optimize the Grinding Process: Adjust the ball size, distribution, and fill level to achieve optimal grinding efficiency and reduce wear on the mill components. Implement a Predictive Maintenance

Contact

Grinding Mills Harcliff

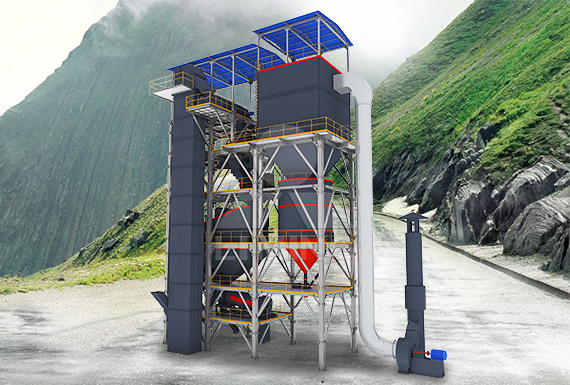

Mill Design, Manufacture Installation. From design and manufacture to installation, commissioning, and a comprehensive aftermarket service, Harcliff mills are designed with cost-effectiveness in mind. Fast-tracked deliveries are undertaken when required. Harcliff sizes and designs new mills to suite and optimise your process requirements.

Contact

ATOX® Coal Mill - FLSmidth

A compact coal mill solution for grinding virtually any type of raw coal. Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate ...

Contact

How it Works: Crushers, Grinding Mills and

2017year6month2day Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can

Contact

IsaMill™ - Glencore

In short, IsaMill™ reduces the energy cost, media cost and capital cost of fine-grinding. The IsaMill™ is used extensively in base metals, PGM, gold processing and magnetite grinding applications. And the power capacity of an IsaMill™ ranges from 75kW to 3.8mW. IsaMill™ is the real-world specification of choice in: ultrafine grinding.

Contact

Maintenance reliability planning AssetCare for grinding

2023year11month15day maintenance costs. It provides a structured and organized approach to ensure that equipment assets are managed in a way that aligns with the organization’s objectives and supports long-term sustainability goals and business success. Applications include ball mills, rod mills, autonomous grinding (AG) mills and semi-autonomous

Contact

Predictive maintenance in mining industry: grinding mill case

2022year1month1day Abstract. The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the hole process: for instance the grinding mills. However, many approaches have been developed by the growth of the mining industry in order to reduce the cost and optimize the time.

Contact

BALL MILL MAINTENANCE - The Cement Institute

Module 1: Welcome and Plant Safety. Module 2: Grinding Systems and Mill Components. Module 3: Ball Mill Inspection and Lubrication. Module 4: Ball Mill Drives. Module 5: Ball Mill Separators, Types, and its Maintenance. Module 6: Fan Design and Applications. Module 7: Introduction to Conveyors. Module 8: Ball Mill Dust Collector.

Contact

Ball Mill Cleaning Maintenance Guide: Extending

2024year4month5day To further enhance your ball mill’s performance and extend its operational life, consider implementing these best practices: Optimize the Grinding Process: Adjust the ball size, distribution, and fill level to achieve optimal grinding efficiency and reduce wear on the mill components. Implement a Predictive Maintenance Program: Use advanced ...

Contact

Predictive maintenance in mining industry: grinding mill case

2022year10month19day Abstract. The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the. hole process: for instance the grinding mills ...

Contact

Grinder vs. Flower Mill: Unveiling the Key Differences

14 小时之前 A grinder is typically used for grinding spices, nuts, and coffee beans into powders or pastes, while a flour mill is specifically designed to grind grains into flour. The finer milling process of a flour mill results in a finer and more consistent flour texture compared to a grinder. Therefore, a grinder cannot be fully interchangeable with a ...

Contact

BALL MILL MAINTENANCE - The Cement Institute

Module 1: Welcome and Plant Safety. Module 2: Grinding Systems and Mill Components. Module 3: Ball Mill Inspection and Lubrication. Module 4: Ball Mill Drives. Module 5: Ball Mill Separators, Types, and its Maintenance. Module 6: Fan Design and Applications. Module 7: Introduction to Conveyors. Module 8: Ball Mill Dust Collector.

Contact

Ball Mill Cleaning Maintenance Guide:

2024year4month5day To further enhance your ball mill’s performance and extend its operational life, consider implementing these best practices: Optimize the Grinding Process: Adjust the ball size, distribution, and fill level to

Contact

Remaining useful life prediction of grinding mill liners using

2013year11month1day Ore grinding mills are heavy duty pieces of equipment that work 24 h a day in highly abrasive environments.From an economic point of view, it is important to keep these mills in operation and minimize the downtime for maintenance or repair, because a drop in production caused by a both scheduled and unscheduled stoppages lead to

Contact

Predictive maintenance in mining industry: grinding mill case

2022year10month19day Abstract. The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the. hole process: for instance the grinding mills ...

Contact

Grinder vs. Flower Mill: Unveiling the Key Differences

14 小时之前 A grinder is typically used for grinding spices, nuts, and coffee beans into powders or pastes, while a flour mill is specifically designed to grind grains into flour. The finer milling process of a flour mill results in a finer and more consistent flour texture compared to a grinder. Therefore, a grinder cannot be fully interchangeable with a ...

Contact

What Preventative Maintenance of Grinding Machines Can

2020year11month3day UNITED GRINDING recommends preventive maintenance of the machines every 2,080 operating hours; this corresponds to one 8-hour shift per day, 5 days a week over a year. If the grinding machine is used in two shifts per day, the recommended maintenance schedule then applies once every six months. Each preventive

Contact

Premier™ Horizontal Grinding Mills - Metso

Metso Premier™ horizontal grinding mills are supported by the use of advanced simulation tools during the design phase. Our tools use 3D technology and evaluate all parameters of the mill design. Ranging from the mill body, to the open gearing to the bearing system. These advanced simulation tools provide a comprehensive view to not only ...

Contact

Hammer Mill Maintenance Pulva

2024year4month12day Hammer Mill Maintenance Guide. Hammer mills are used in various manufacturing processes to grind products into different feeds, such as those used for pets and livestock, or for grinding or processing seeds into oils, among other applications. Regardless of what a hammer mill is used for, it must be adequately maintained.

Contact

Mining Mills AllMinings

2024year2month22day Coarse Grinding: AG mills are often used as the primary grinding stage in mineral processing circuits to reduce the size of ore particles before further processing. Reducing Maintenance: The absence of grinding media in AG mills reduces wear and tear on the mill’s components, potentially leading to lower maintenance costs.

Contact

Hammer Milling and Jet Milling Fundamentals AIChE

2017year6month3day The jet mill is primarily used for superfine grinding applications and creates particles sizes down to a few microns. Understanding the fundamentals of each mill’s respective grinding mechanisms, operating philosophies, and best maintenance practices is essential to achieving good product quality, energy savings, and high throughput.

Contact