المنتجات الساخنة

Derivation and validation of a coal mill model for control

2012year5month1day The paper presents development and validation of a coal mill model to be used for improved mill control, which may lead to a better load following capability of

Contact

Process monitoring and abnormal reason tracing of coal mill

Abstract: Coal mill is the main equipment in the industrial pulverizing system. It is the key to ensure the stable and efficient operation of the pulverizing system to effectively use the

Contact

Multi-objective Optimization of Coal Mill Outlet

In this paper, we present a Model Predictive Control (MPC) based strategy to address the complex problem of coal mill outlet temperature control, which requires the collaborative

Contact

Coal Mill Control and Optimization Using a Multilayer Structure

Ball mill coal pulverizing system is a multiple-input multiple-output (MIMO) process characterized with strong couplings and nonlinearities. Conventional control methods

Contact

CPRI - Online Coal Flow Balancing and Fineness

2020year3month19day Online coal flow measurements in combination with variable orificing valves allow the simultaneous measurement and closed-loop control of the coal flow and

Contact

Analysis of the Coal Milling Operations to the Boiler

2021year10month28day Milling system in coal power plant purposely to process the raw coal to become as pulverise fuel before enter to the boiler furnace. Pulverise fuel enter to the

Contact

A unified thermo-mechanical model for coal mill operation

2015year11month1day Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills. In this paper,

Contact

An investigation of performance characteristics

DOI: 10.1080/19392699.2020.1799200. Authors: Mehmet Tontu. Iskenderun Energy Generation and Trade Co. Citations (10) References (27) Figures (15) Abstract and Figures. This study shows the...

Contact

Process control optimization of rotary kiln line, raw mill and coal ...

The rotary kiln line, raw mill and coal mill were being operated by a PLC based central automation system in the plant. In general, it is quite difficult to ensure process control

Contact

Dynamic Comprehensive Risk Assessment of Coal Mill Based

Coal mill is an important equipment in cement production line, and also the focus of personnel inspection. The inspection and maintenance of coal mills rely on the experience and system of personnel. Daily maintenance still stays in the state of post-maintenance, and lacks real-time dynamic fault risk assessment for equipment abnormalities. Aiming at this

Contact

Bowl Mill Coal Pulverizer

6 天之前 1. The hot air dries the coal. 2. The hot air is used for transportation of the recirculating coal within the mill and also for. transporting the coal from the pulverizer to the furnace. As the coal is continuously reduced in size, the smaller/lighter particles are swept from the bowl by the hot air. Hot air (and cool tempering air) is provided ...

Contact

Multi-objective Optimization of Coal Mill Outlet

In this paper, we present a Model Predictive Control (MPC) based strategy to address the complex problem of coal mill outlet temperature control, which requires the collaborative management of outlet temperature and incoming mill air flow. Our approach demonstrates significant improvements in temperature stability, control accuracy, and energy efficiency.

Contact

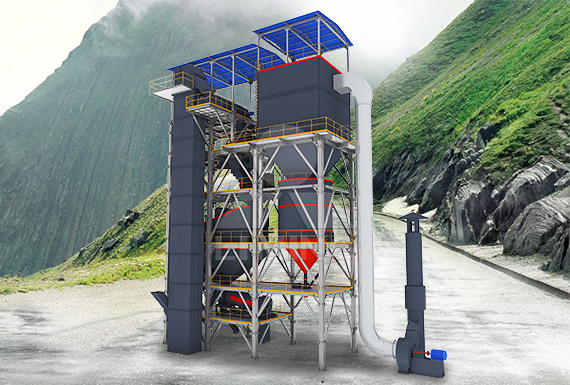

Cement Production Line

2023year4month12day GRMC16.21 Vertical Coal Mill Φ3.5×54m Rotary Kiln : Φ3.5×13m Cement Mill : 2500 t/d : GRMR38.41 Vertical Raw Mill : GRMC20.31 Vertical Coal Mill ... 1500 t/d Cement Production Line The new dry process cement production line with a capacity of 1500t/d built by Xinxiang Great Wall Machinery Co., ...

Contact

MPS mills for coal grinding - AYS Engineering

2021year3month12day 2 Design features of MPS mills for coal grinding. Depending on the material to be ground, throughput rates of 5-200 t/h can be achieved in a fineness range between 1% R0.063 mm and 25% R0.090 mm. Thus, the MPS coal grinding mill device for fresh material is arranged in this area where the fresh feed is also mixed with the grits

Contact

sbm/sbm weathered coal mill production line weathering.md

redmik40/sbm development by creating an account on GitHub.

Contact

An intelligent expert system (KBOSS) for power plant coal mill ...

1997year1month1day These faults cause deviations in the measured/ unmeasured process variables i.e. symptoms, which can be useful to detect these faults. The researches done on mill fault detection using model based techniques are presented in ([Fan Rees (1997),Odgaard Mataji (2006),Odgaard Mataji (2008),Odgaard, Lin, Jorgensen

Contact

Study the kinetics involved in solid state reduction of mill

2021year1month1day 1. Introduction. The coal-based direct reduction process produces metallic iron from ferric oxide under the solid-state. Normally it is observed that when the reaction temperature is low, the reduction rate will be slow [1].On the other hand, when the reaction temperature is too high, it is prone to bond and will cause a waste of energy.

Contact

China Cement Production Line Manufacturer, Rotary Kiln,

China Cement Production Line Supplier, Rotary Kiln, Roller Press Manufacturers/ Suppliers - Jiangsu Pengfei Group Co., Ltd. ... 800tpd Dry Process Cement Production Line FOB Price: US $16,000,000 / Piece. Min. Order: ... 2.4* (4.5+2) Air Swept Coal Mill in Cement Production Line Min. Order: 1 Piece Contact Now. Video. Vertical Roller Mill Used ...

Contact

Early Warning of Critical Blockage in Coal Mills Based on

Using the historical data of coal mills obtained from existing distributed control systems (DCS), the constructed SDAE framework is capable of issuing a criti-cal blockage warning at an early ...

Contact

A new model-based approach for power plant Tube-ball mill

2014year4month1day Hot air is swept through the mill by two variable speed fans, and the air acts as both the drying and transporting agent for the coal. If the coal mill heating process is treated as it happens in an isolated environment as shown in Fig. 4, the heat input into the coal mill and the heat output from the coal mill complies with the heat balance rule.

Contact

TECHNICAL MODIFICATION OF NEW DRY PROCESS ...

2013year3month13day capacity, the fineness of pulverized coal must be effectively controlled. If big increase of coal mill capacity not required, it generally will modify or optimize separator. If it requires big increase of coal mill capacity, technical modification and optimization to

Contact

Coal mill, gypsum mill, clay mill, etc. Pfeiffer

The thermal energy of process gases – even at low temperature - can be used on MPS mills. High availability . ... MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine. MPS 3070 BK coal mill, Jaypee Cement

Contact

A Wear Condition Monitoring Model of Coal Mill Grinding

2020year10month14day A Wear Condition Monitoring Model of Coal Mill Grinding Roller Based on LSTM. October 2020. DOI: 10.1145/3434581.3434628. Conference: ICASIT 2020: 2020 International Conference on Aviation Safety ...

Contact

How to Process Coal into Pulverized Coal in 5 Steps?

2024year1month11day 1 You start by mixing water with pulverized coal to form coal slurry or pulp. 2 Add some floatation reagents, also known as collectors and frothers, to the slurry. For pulverized coal, the typical dosage of flotation reagent is 0.5 to 1.0 kilograms (1.1 to 2.2 pounds) of reagent per tonne of coal feed.

Contact

Coal mills for all requirements Gebr. Pfeiffer

Coal, lignite or petcoke are ground in the Pfeiffer vertical mill by using available hot process gases. The grinding plant can be inerted. The raw coal is dried while being ground in the mill even if feed moisture exceeds 25%. The feed size that can be handled is up to 100 mm, making two-step pre-crushing unnecessary.

Contact

Fault Diagnosis of Coal Mills Based on a Dynamic Model and

2023year9month15day Abstract. As the significant ancillary equipment of coal-fired power plants, coal mills are the key to ensuring the steady operation of boilers. In this study, a fault diagnosis model was proposed on the basis of a dynamic model of a coal mill and deep belief network (DBN). First, a dynamic coal mill model that considered the joint influence

Contact

Grinding process within vertical roller mills: experiment and ...

2009year1month1day This paper describes the simulation of the grinding process in vertical roller mills. It is based on actual experimental data obtained on a production line at the plant and from lab experiments. Sampling and experiments were also carried out in a power plant that has four ball-mill circuits used for coal grinding so that different equipment ...

Contact

An investigation of performance characteristics and

2020year8month12day Tontu [14] investigated the relationships between the current, coal feed, grinding pressure, and primary air and outlet temperatures of coal mills, and proved that a high correlation exists ...

Contact

Coal Crushers Coal Pulverizers Mills Williams Crusher

Contact us today to discuss your application in detail with one of our experienced sales engineers. Call (314) 433-5464, email us at info@williamscrusher, or locate an agent near you. Williams Patent Crusher has become the industry leader in coal-crushing and pulverizing equipment. Learn more about our products.

Contact